Sustainable Smart Parasites (SSP) aims to create objects that extend our human capacity to connect with one another, in an energy-conscious way. Using printed electronics*, the project explores the benefits of the connected world we live in, without relying on the vast power outputs that it currently requires.

Envisioning the future of smart sustainable parasites – a new approach in the design of technology-enabled sustainable objects and systems.

Over the last decade, the idea of “connectivity” and its more profound implications popped up, bringing unprecedented opportunities to reinterpret the surrounding of modernity. Interconnected devices are redefining the interaction paradigms between human beings and their bodies, the object they own, and the space they belong to. However, the human body, traditional objects, and the space are not inherently interconnected and necessitate an “extension”, to enhance their functionalities. Since such extensions only have meaning and function when attached to the object they need to improve, they can also be defined as ‘parasites’.

→ Read more

The evolution of parasites into a different class of technology-enabled objects or smart parasites is inevitable. Still, it carries a series of criticalities which have not been entirely addressed so far by either industry or the scientific community. One of the most significant is related to sustainability. The SSP project challenges current perspectives of printed electronics and envisions and defines new functions, methods, and production tools for future Smart Parasites that are environmentally friendly, have a low carbon footprint for all its lifecycle and are energy conscious with low production costs. To pursue these ambitious goals, we exploit the recent advances in printed electronics and ad-hoc manufacturing to produce devices and concepts based on enhanced electronic functions. We are facing three ambitious goals by employing a design-driven approach, with a strong synergy between design and technology experts. First, we aim to obtain prototypes of sustainable smart parasites in the three categories: human body parasites, object parasites, and space parasites. Secondly, we will use the expertise and know-how gained through the project to create novel tools and equipment for the environmentally friendly fabrication of smart parasites. Finally, the research on structural and functional materials will lead to the definition of a database of materials, where the aesthetic and functional properties of the materials are classified and described. We believe that the successful actuation of this project will pave the way to an entirely new approach to the design of technology-enabled objects and sustainable systems.

An interdisciplinary research project

Free University of Bolzano

Faculty of Design and Art

Faculty of Science and Technology

Year

2018 – 2023

Team

Nitzan Cohen

Ignacio Merino

Prof. Paolo Lugli

Prof. Luisa Petti

Dr. Martina Aurora Costa Angeli

Dr. Mallikarjun Madagalam

Dr. Christian Ebner

Dr. Giuseppe Cantarella

Photography

Foxhole Radio

What if the radio waves could solely power an emergency radio?

The Printed Foxhole Radio is a self-powering radio that harvests the energy it receives from the radio waves. Based on the same principles behind the original Foxhole radios DIY (do it yourself) made from simple found materials by allies’ soldiers in World War II. They were isolated in different places and wanted to have a radio to get news from the world.

Fascinated by the simplicity of the harvesting principle behind the Foxhole radio and the evident compatibility with the printed electronics logic, this project merges the two. As a result, it offers an innovative, renewed view of this 80-year-old ingenious invention.

Battery free emergency radio receiver

Exploded view of printed components

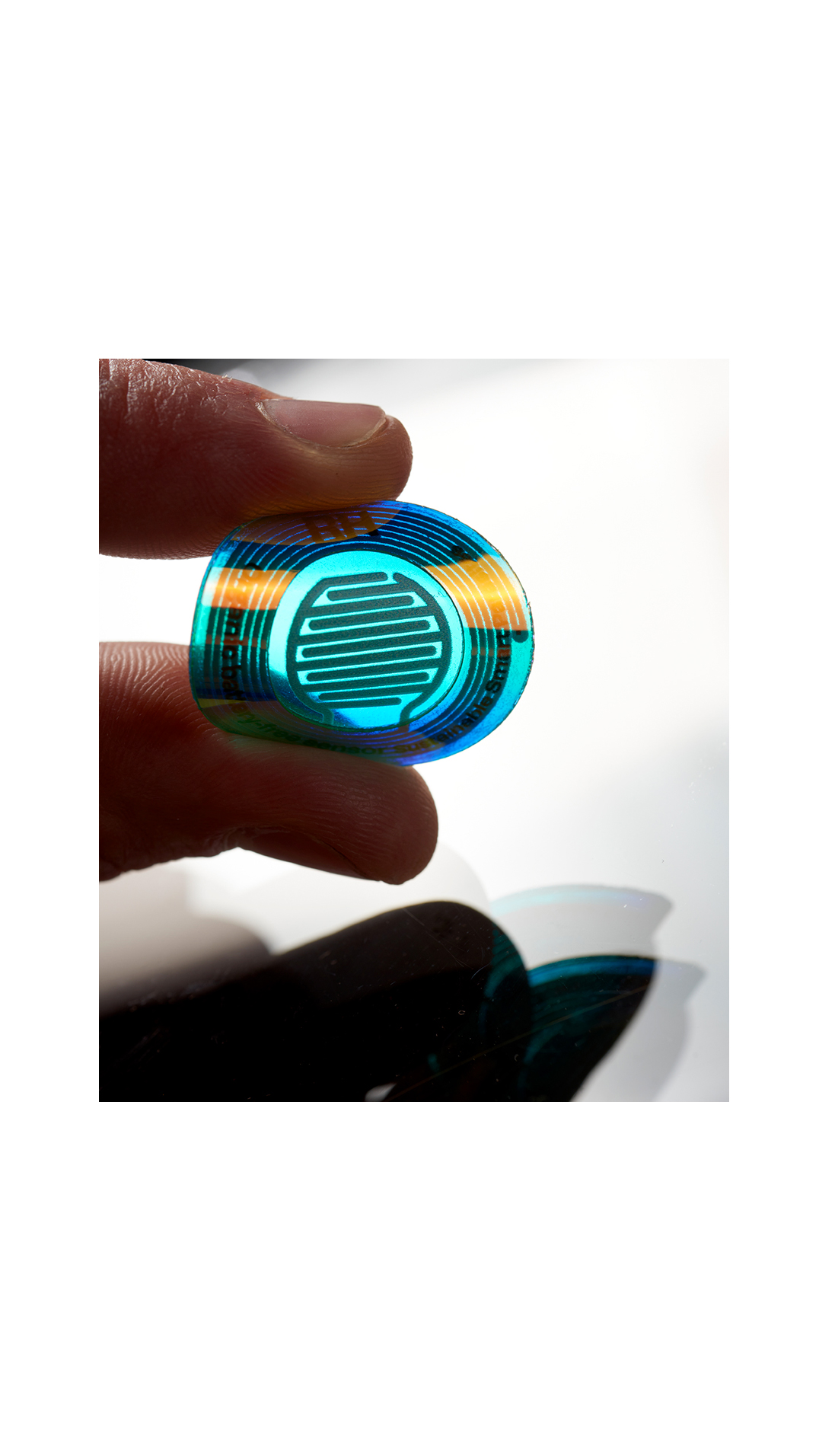

The main electrical components are printed with special conductive ink made of silver-nano-tubes. Among those are the antennas that serve as signal receivers and energy harvesters and the stunning circuit (coil and capacitor), specifically tuned to the international radio emergency frequencies.

Explanation of our hybrid electronics.

The whole electronics architecture could be defined as a hybrid since it merges silicon and printed electronic components. For example, the diode bridge and the piezoelectric crystal earpiece are assembled with printed electrical components.

The design featured here is a conceptual prototype based on real data, specifications, and application perspectives.

Kitchen Softscale

What if your kitchen scales never ran out of battery?

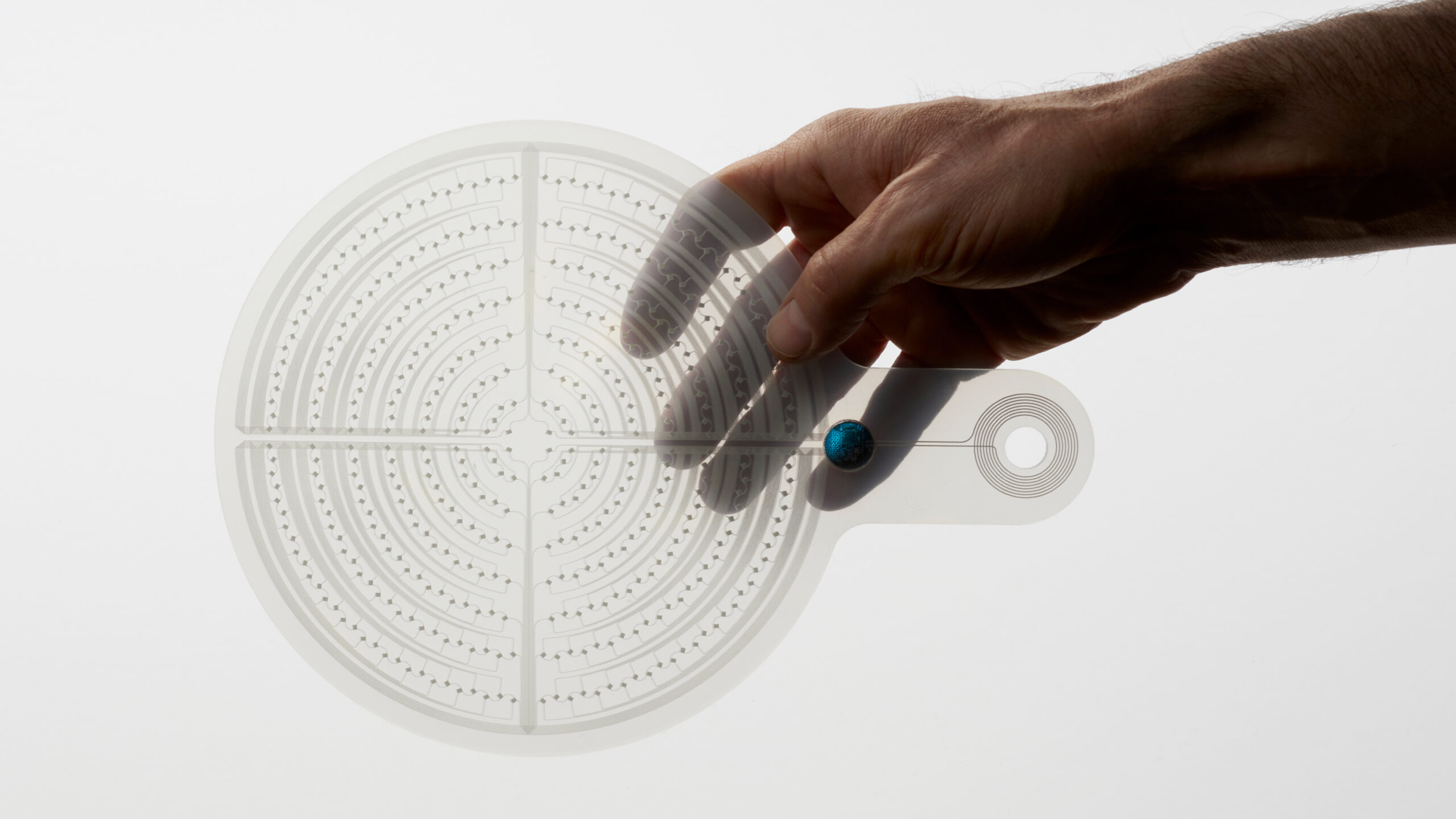

Printed electronics can re-imagine weight measurement using the surface tension of a soft, malleable silicon membrane. As a result, the scale becomes almost immaterial, comprising only a remarkable membrane-printed stretchable sensor array with an integrated receiver/transmitter. The same technology is used to measure a gram, kilogram, or ton, making it suitable for measuring practically anything.

Soft scale operation

Exploded view of printed components

When an element is placed on the printed kitchen scale membrane, it creates a deformation in the membrane surface. Even the slightest deformation changes the electrical charge in the circular array of stretch sensors (printed with conductive silver-nano-ink). This change is directly translated into a high-precision weight reading.

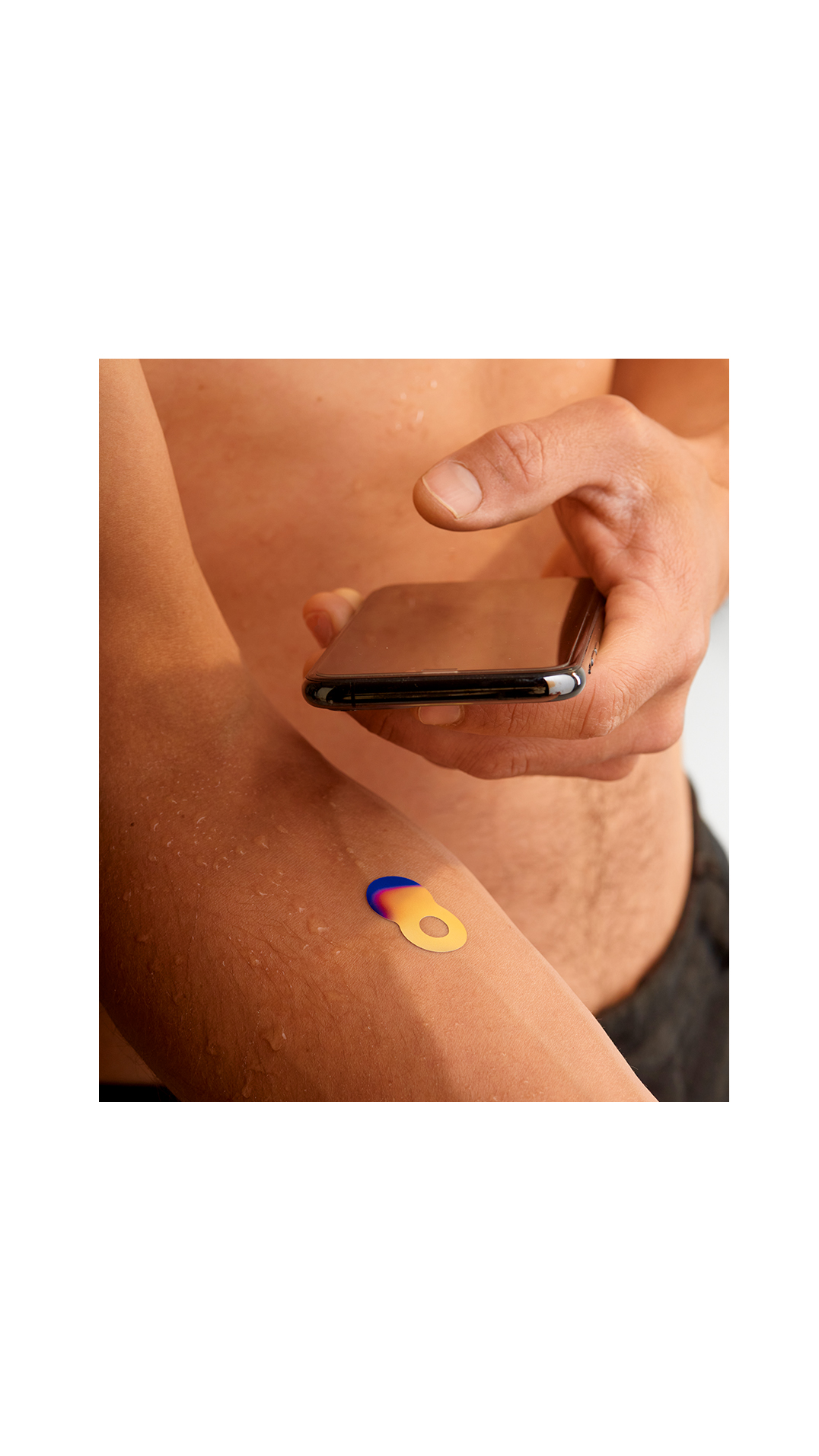

The printed kitchen scale is powered by connecting to a smartphone using reverse induction charging technology. The smartphone acts as an information processor and user interface.

Simply placing a smartphone in the allocated position automatically activates the scale. A dedicated app offers a broad scope of functions and a rich user interface.

The design featured here is a conceptual prototype based on real data, specifications, and application perspectives.

Personal Softscale

What if your personal scales could be as bright as your smartphone?

The printed personal soft scale is based on the same principles and techniques as the Printed Kitchen Softscale. The larger surface of the personal scale enables the integration of a higher number of sensors compared with the kitchen version. This provides increased accuracy readings in the broader weight range.

When a person steps on the printed personal scale membrane, it creates a deformation in the membrane surface. Even the slightest deformation changes the electrical charge in the circular array of stretch sensors (printed with conductive silver-nano-ink). This change is directly translated into a high-precision weight reading.

Publications

Laser-Induced, Green and Biocompatible Paper-Based Devices for Circular Electronics

The growing usage and consumption of electronics-integrated items into the daily routine has raised concerns on the disposal and proper recycling of these components. Here, a fully sustainable and green technology for the fabrication of different electronics on fruit-waste derived paper substrate, is reported. The process relies on the carbonisation of the topmost surface of different cellulose-based substrates, derived from apple-, kiwi-, and grape-based processes, by a CO2 laser.

Cantarella G, Mallikarjun M, Merino SanchezFayos I, Ebner C, Ciocca M, Polo A, Ibba P, Bettotti P, Mukhtar A, Shkodra B, Inam AKMS, Pour Yazdan A, Paganini M, Tiziani R, Mimmo T, Cesco S, Münzenrieder N, Petti L, Cohen N, Lugli P.

Journal for Advanced Functional Materials / 2023

Fabrication and characterization of flexible planar electrodynamic loudspeakers. Conductive spirals are fabricated on a flexible and transparent polyethylene terephthalate substrate via screen printing. Different geometries (circular and rectangular) and sizes of the conductive spirals are investigated to understand their impact on the performance.

Madagalam M, La Torraca P, Ahmed M, Douaki A, Merino SanchezFayos I, Cohen N, Petti L, Lugli P.

Proceedings of the 6th IEEE Electron Devices Technology & Manufacturing Conference (EDTM) / 2022

Since its first discovery in 2014, laser-induced graphene (LIG) has gained increasingly attention as a simple and low-cost alternative to printing techniques, which instead require additional materials such as functional ink or adhesive layers. While there are several works on LIG supercapacitors, gas sensors, and triboelectric generators, this method is still very unexplored for antennas, especially if realized on eco-friendly paper substrates.

Ahmad M, Cantarella G, Costa Angeli M, Madagalam M, Ebner C, Ciocca M, Riaz R, Ibba P, Petrelli M, Merino I, Cohen N, Lugli P, Petti L.

Proceedings of the International Flexible Electronics Technology Conference (IFETC) / 2021